As director of product management at GRAS Sound & Vibration, Rémi Guastavino defines the new product strategy for the test equipment maker, which industries their products should be aimed at, and how they can be improved to address the needs of the customer.

With a PhD in acoustic and measurement methodology and a 12-year stint at sound and measurement equipment specialist Brüel & Kjaer, Guastavino already had a wealth of experience in the acoustic precision testing before joining GRAS.

This experience was vital since GRAS Sound & Vibration are one of the most prestigious names in acoustic testing. Founded in 1994 by Danish acoustics pioneer Gunnar Rasmussen, GRAS has since grown to be a worldwide leader in the sound and vibration industry, developing measurement microphones for use in product testing and development.

CET&D: Tell us a little about your background?

Guastavino: I have always worked in the acoustics industry. I studied engineering physics with a major in sound and vibration at KTH Royal Institute of Technology at Stockholm. This is where I began to attend some lectures on acoustics, and I found the subject to be really interesting. I continued with it and earned my undergraduate degree. I then pursued my PhD, which led to a position as a domain specialist for acoustics at Brüel & Kjaer. Here, I started to work on improving the next generation of microphones. Acoustic measurements are exceedingly tough, and many people do not measure accurately because of the complexity, and generally not well-covered at universities. However, as a team, we worked on how to help users make better measurements and how to decrease the complexity level, making it simpler for them—that’s the aim. After Brüel & Kjær, I joined GRAS. So, yes, working in acoustics has always been my passion.

CET&D: Tell us about how you tailor your products for your customer’s needs?

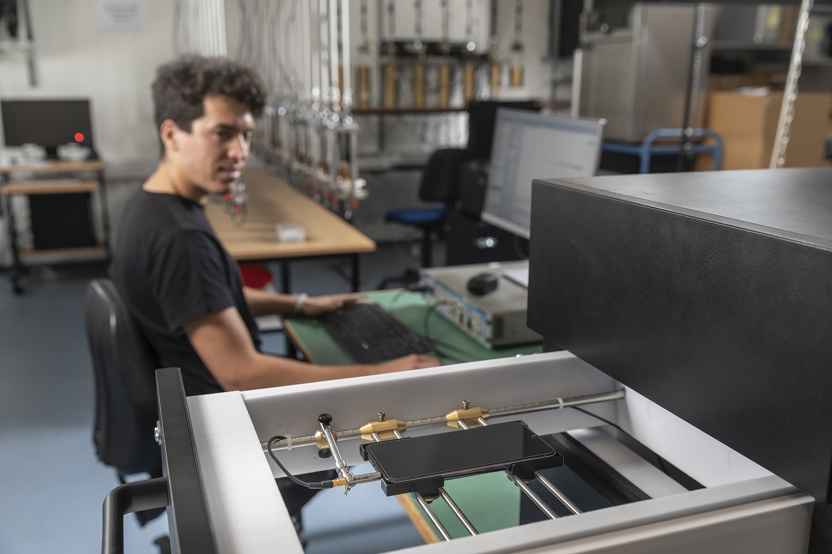

Guastavino: For example, we have a new product, EQ 40PM microphone, that we designed for use on a production line. When you purchase a mobile phone, you'll notice that it has about three or four microphones and two or three speakers. These need to be tested on a production line before they are distributed to customers. The price of a mobile phone can be extremely high, and for that price, customers expect good quality. Operators on a production line tend to be less educated in acoustics. If you’re selling a microphone to a university, for example, they know how to use our products, they know how to do compensations, set the sensitivity etc. However, production lines are designed to increase the speed to produce goods much faster, and production line staff who haven’t been trained in acoustics will struggle to learn. This is why the ease-of-use for this latest microphone is much higher.

Acoustic testing of smartphone with GRAS' EQ 40PM microphone. Picture: GRAS Sound & Vibration

CET&D: What kind of consumer electronics companies use your products?

Guastavino: Any companies for whom sound quality matters. Take high-end headset manufacturers, as one example. This kind of company will buy a measurement microphone because their customers expect excellent sound reproduction, and the company’s reputation will suffer if the quality is poor. They also need to ensure that noise cancellation is optimized and that requires a known correlation between the microphones. This cannot be achieved without a high degree accurately. Other consumer electronics makers that use our products include tech companies that make mobile phones, tablets, and smart speakers. Anytime you need to measure something accurately you should use our microphones.

Traditionally, if you were to buy a microphone for a production line, there would have to be a setup procedure with the microphones, there would have to be calibration, there would have to be dry tests to ensure that, when the production line starts, the microphones and the whole audio are set up properly. With these new microphone technologies such as the EQ 40PM microphone that GRAS has developed the time used to this procedure is reduced to a minimum as there is no individual adjustment. Effectively, you open the box, take the mics out of the box, plug them in and away you go! They look the same as other production line microphones, but it’s the internal intelligence of the microphone that is making it happen. Thus, the cost and set up time are reduced, over and beyond the general low cost of the microphones themselves. This is the first time this technology has appeared on the market. No other company has done this to date.

CET&D: Are your products used in the testing of voice recognition systems like Alexa?

Guastavino: Yes, so if you take an Alexa speaker, you’ve got an array of maybe 8 or 10 microphones so that you are able to hear people in different locations and you can make some algorithms that when people talk the music comes down so the computer can understand it. For us it’s really good as those 8 speakers must be tested regarding the new features that you get in voice technology, making it more complex. This also means that more microphones are needed in the device, so they’ll come to us and use our microphones to adjust and test the microphones in their smart speaker. Essentially, we’re helping the company to adjust the microphones that are in their products by using our microphones. They adjust theirs by comparing to ours.

GRAS' EQ 40PM microphone promises to simplify production line acoustic testing. Picture: GRAS Sound & Vibration

CET&D: Does AI or machine learning play any part in your work?

Guastavino: We don't yet have any products that use AI, but it's something we're looking at and should be working on. However, the acoustic measurement sector is pretty conservative; it takes time. Just having a microphone with some form of digitization inside was a big step and the first time in the industry for it to happen, so I don't think we’re ready to go down the AI route just yet; however, it's something we're definitely working toward.

CET&D: Can you tell me about the part that interfacing with customers plays in your job?

Guastavino: Talking to customers and getting their feedback is a huge part of my work as it’s important that we find out what are their needs, what are we not achieving, and if there is a technology solution that we can provide or develop to achieve what the customers want. That’s a key element of our business strategy.

I also do coaching, as educating others on acoustic measurement is particularly important to me. COVID was a difficult time as most interactions occurred on Teams. However, now that I’m allowed to travel again, it is great to have real interactions and meet people face to face.