I haven’t count them, but I am sure during my last 15 years working for Atlas Material Testing Technology, the question of how long should one test has probably has come up at least once every month.

The question about the right test duration is an important question because time - especially during product development - is valuable. The best approach to answer this question is first to identify the motivation, why we are going to run a weathering test. In my experience, most weathering tests can be split into three different categories:

1. Durability screening of materials for new products

2. Material qualification for new products

3. Service lifetime testing of new products

Durability Screening

Material durability screening is an early-stage tool to pre-select the best candidate materials for a new product. In the case of lightfastness/weathering testing, it is basically a UV-durability test. When done inside a full-spectrum xenon instrument, it is additionally a visible light check especially important for all colored materials.

Material screening can often be done by using a short-term version of the material qualification test. Helpful to this are easily detectable (for example, visual) defined pass/fail criteria for the screening test. For example, a typical fail-criteria would be a detectable color change. Depending on the material durability and type of product, test durations can be rather short - within one to several days.

Material Qualification

Material qualification often follows a given standard test method. For example, a validated test from a company to whom you supply your materials or components (a specifier). Those qualification tests often have a minimum test duration and clear pass/fail criteria. The test duration is often related to a specific radiant exposure (radiation energy).

For example, the exterior material test for Volkswagen (PV 3930, also known as the Florida test) requires a radiant exposure of 350 MJ/m2 at 300-400 nm by setting the irradiance to 60 W/m2 at 300-400 nm. With these settings, the required radiant exposure is achieved with a 1620-hour test duration.

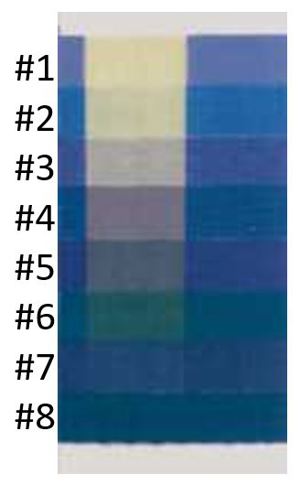

Another way to determine a defined test duration is based on a reference or control material such as the Blue Wool reference. Their fading behavior can be visually evaluated by the use of an ISO grey scale. The test duration of lightfastness tests for printing materials, textiles, or leather often makes use of these blue wools.

For example, clients following the ISO 12040 test for printed matters typically run their test until Blue Wool no. 4 achieves a fading equal to the contrast of grey scale 3 (~ 45-50 h) between an exposed and an unexposed portion of the fabric.

If their material shows comparable fading like Blue Wool no. 4 that means it has “good” color lightfastness under solar radiation. However, should it look like the less stable Blue Wool #2, then the color lightfastness would be rated “low”.

Again, test durations depend on the material durability and service lifetime of the product you are trying to achieve. Typical test durations lie in the range of 24 up to a few thousand hours.

Service Lifetime Testing

While the above concepts make use of weathering testing as a directional decision-making tool, answering the question: 'Will the product most likely perform until the expected service-life or prematurely fail?', service lifetime testing tries to find out as precisely as possible how long a material will perform in a chosen environment/region.

This typically requires many years of laboratory testing assisted by parallel natural weathering to study and understand product degradation mechanisms. Finally, it is important to always make use of statistical and mathematical tools to determine the acceleration factor of their laboratory test vs natural degradation.

This article was written by Dr Oliver Rahäuser, senior product manager at Atlas Material Testing Technology and first appeared as a blog post on their company website. It is only reproduced here with their kind permission.