Eric Eisenberg has been working at Radiant Vision Systems (RVS) for the last 12 years. Based in Redmond, in Washington state, RVS develops advanced imaging systems to critically evaluate light, color, manufacturing integrity, and surface quality of illuminated displays and device assemblies.

During his time there, Eisenberg has worked as an optical software engineer, which led him to build and manage an applications engineering team responsible for the deployment of RVS’ systems into its customers’ facilities. Eisenberg now leads the optical engineering and hardware test engineering teams at RVS. “Innovation is the lifeblood of our business,” said Eisenberg. “It is imperative for us to continue to develop new solutions for where we see the market going in the next one to many years.”

CET&D: Tell us about RVS’ history and the services it provides?

Eisenberg: Radiant specializes in measuring light and color as they are perceived by the human eye. This can be light from lighting devices such as automobile headlamps, luminaires for room lighting, or illuminated display devices such as smartphones and television screens. Radiant provides the equipment that manufacturers can use to measure and inspect DUTs (a ‘device under test’) to assess their functionality, performance, and quality. Our ProMetric® imaging photometers and colorimeters take 2D images which reveal defects such as dead pixels on a display and are particularly effective at evaluating uniformity by comparing all areas of the image at once.

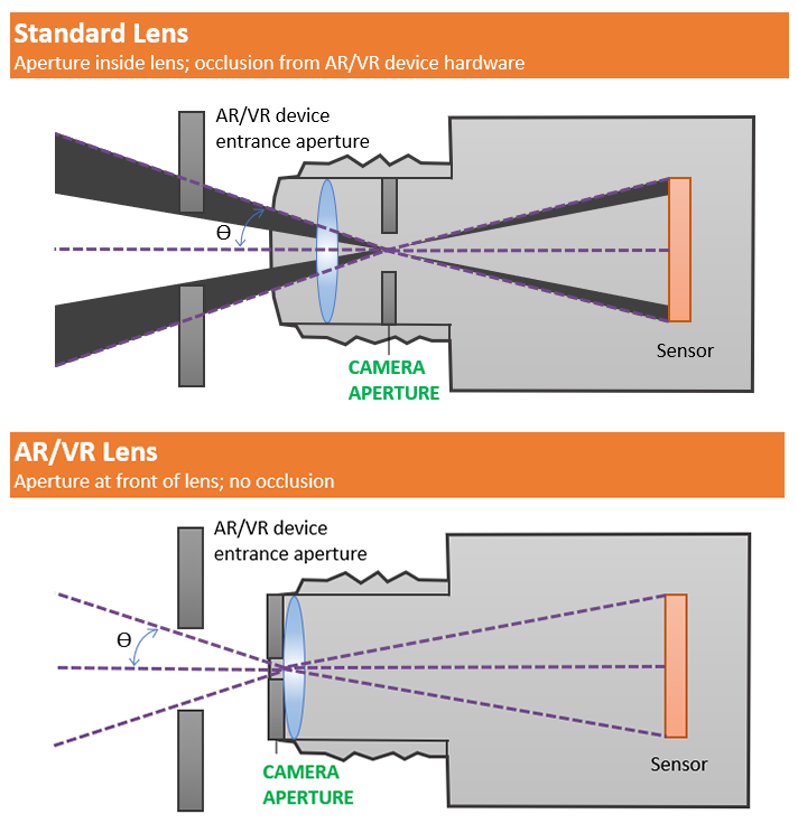

A graphic illustrating the differences between a standards lens versus a AR/VR lens. Picture: Radiant Vision Systems

CET&D: Why is display testing important in the consumer electronics industry?

Eisenberg: Humans have very acute visual processing capabilities so even small defects on a display are immediately noticeable, whether it may be individual items like a dead pixel, or broader issues with uniformity across a display. These issues can lead to costly returns and replacements for manufacturers. Consumers expect high-quality performance and appearance from the electronics products they purchase.

CET&D: Can you share any notable RVS solutions that have benefited the consumer electronics industry?

Eisenberg: Radiant pioneered a technology we originally called “OLED Correction” into something that’s sold as “Demura” today. This started with work the company did many years ago with the correction of LED display boards with a product called VisionCAL. Radiant’s demura technology is used to correct many of the displays sold in consumer electronics today.

CET&D: What are the most important qualities to possess in your role?

Eisenberg: It is important to recognise the pace at which this type of technology evolves and to make sure we provide solutions that solve our customer’s problems in a timely manner. Encouraging my engineers to consider innovative solutions, understanding that failure is part of success, and making sure they know how and when to get any of the help they need.

CET&D: What factors need to be considered when testing AR/VR/MR device displays?

Eisenberg: There are additional considerations for AR/VR/MR (collectively XR) device displays because they are worn very close to the eye. Headset developers have to consider user comfort and well-being. To avoid issues such as dizziness or motion sickness, XR devices must be carefully designed and tested. Displays in the transportation sector such as automobile dashboard panels have an additional level of requirements to meet stringent standards for color, brightness, and other factors based on regulations in different countries.

CET&D: How do you address the unique quality requirements of displays in VR/AR/MR devices?

Eisenberg: There are two major challenges in evaluating AR/VR/MR displays. First, the unique specifications and visualization parameters of a display intended for viewing at close range inside a headset requires a different approach than traditional flat-panel displays. To understand the true quality of a display in this context, we needed a system that could replicate the viewing conditions of the user; a lens that could capture a wide field of view (FOV) of visual elements at close proximity to the display in the headset, similar to the human eye.

There was no lens capable of what we needed to do, so Radiant developed our own lens—which we aptly call the AR/VR Lens. The two hallmarks of the lens are its wide-FOV optics (which allow it to capture up to 120° full-angle horizontal FOV) and the entrance pupil at the front of the lens, rather than embedded inside the housing. By designing a lens with the aperture at the front, we’re now able to put the ‘eye’ of our imaging system at the user’s eye position and see everything the user can.

The second major challenge for evaluating AR/VR/MR device quality is the incredible variety of device designs, form factors, optics, and display technologies—no two headsets are configured the same. In the R&D phase, headset designers also need to make rapid adjustments and build multiple prototypes.

What Radiant set out to do is address this wide range measurement needs by leveraging all of our existing imaging and software technology, using them as building blocks to develop new solutions and address new requirements. Not only does this provide a lot of opportunity for creative design by our optics development team, but we’ve also found ways to remain nimble and efficient using some very fundamental technology.

CET&D: What is your latest product for VR/MR/AR devices?

Eisenberg: The XRE Lens is a product derived from a patent-pending invention that uses off-the-shelf components to produce a range of ‘custom’ optical test system architectures without the time, cost, and complexity of a fully custom lens. This is unique to test systems on the market. Manufacturers’ devices and specifications can be so exclusive that a ground-up optical system needs to be designed for each test case. With the XRE Lens, we have reduced optical test system development cycles which can make the solution adapt quickly to changing requirements as the manufacturer’s specifications change.

Since we don’t foresee standardization across AR/VR devices, we expect to continue to develop solutions to address more headset diversity based on the flexibility of our XRE Lens solution as a platform. We have already developed lenses with a 23-degree and 57-degree half-angle FOV to meet different customer inspection needs.

The XRE Lens has a unique optical design and electronic focus specifically engineered for measuring near-eye displays, such as those integrated into virtual (VR), mixed (MR), and augmented reality (AR) headsets. Picture: Radiant Vision Systems

CET&D: How do you see the AR growing/evolving in the next 5 years?

Eisenberg: The parallels between what’s happening today with AR devices and smartphones 17 years ago are really uncanny. 17 years ago, I had a PocketPC manufactured by HTC running Windows Mobile. I remember using it to watch a movie in a park and people were staring at me and thought it was so strange. Then along comes Apple with their iPhone and they made what was a geek’s dream toy into a mainstream device that ultimately became the most successful consumer electronic product ever sold. They did this with excellent design, accessibility, and a seamless experience that even a small child can execute successfully. I fully expect Apple to do the same thing with augmented and mixed Reality.

CET&D: Tell us about any new technologies that you are developing?

Eisenberg: Roughly 62-67 percent of people globally wear prescription lenses of some kind. For AR/MR, RVS is working on addressing the prescription vision issue. It’s a real challenge for display measurement systems to compensate for the vast range of permutations for near-sightedness, far-sightedness, and/or astigmatism. It’s essential for a metrology system to be able to compensate for these corrective optics.

Also, AR and VR devices are getting brighter, higher resolution, wider field of view, etc. Radiant already has some very high-resolution systems and continues to invest in this direction.

CET&D: What’s the secret of staying competitive?

Eisenberg: A key principle we need to keep in mind is to never get complacent, the competition is fierce and always nipping at our heels. There is a limited window for any new technology we develop to be sold effectively before our competitors release their response. Innovation will continue to be the key to our success and our survival.