Unfortunately, many products fail electrical safety testing and certification the first time. This frustrating fact is something that is often easily avoidable had the product’s electrical safety requirements been considered earlier and more thoroughly.

Safety testing, the safety approval process, and the applicable standard(s) should be considered during the product’s initial design and concept. If a design team is unaware of the requirements the product will have to meet in terms of regulatory compliance, it is not surprising that the product later fails approval. A common product pathway is to design the product before selecting the standard, leaving someone with the unenviable task of then trying to fit the product to it. If a product is designed to a specific standard from the outset, and a copy of the standard is kept to hand throughout the product’s development, it is far less likely that it will then have any issues when it comes to regulatory approval. This approach can save considerable time and money, helping to avoid costly re-designs and unnecessary delays to market.

Achieve success first time

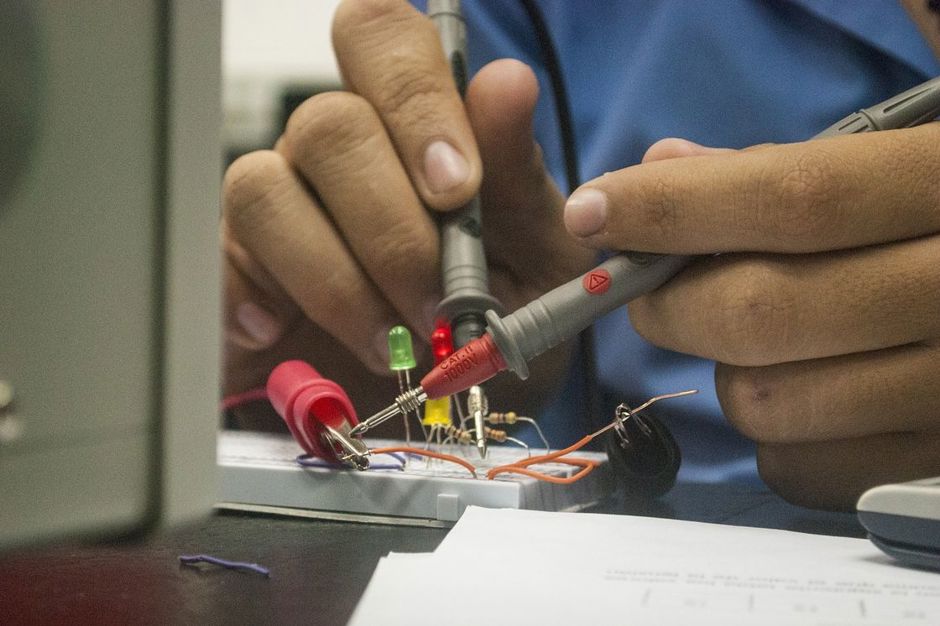

While avoiding failure depends on the specifics of the relevant standard and the product in question, there are key points that can frequently help avoid it. A key target should always be to achieve success first time at the testing, approvals, and certification phase. These are Element’s electrical safety team’s top tips to avoid some of the most common causes of products failing:

Avoid unnecessary delays due to EMC failures

EMC design mistakes that result in a product failing EMC testing are extremely common. EMC testing usually requires considerable customer involvement, so it is usually best if it is undertaken before other safety testing. If a product fails at EMC, components will potentially need to be changed or adapted to address the failure which may affect safety compliance. EMC and safety pre-compliance evaluations and testing can cut the risk of this happening. Seeking advice early to prevent future issues will always be the safer and more cost-effective option. Element’s Advisory Services work with a manufacturer’s product development and design teams to keep them informed of future requirements and ensure the product’s compliance pathway has been carefully considered.

Consider creepage and clearance distances

A significant part of any safety compliance testing will be to check the creepage and clearance as required by the standard. Ensuring the printed circuit board (PCB) layout is right at the beginning can really save time and effort later. The standards will define the minimum required creepage and clearance distances allowed. The distances may vary between standards, so it is essential to understand which standard your product will be tested against and ensure a copy is available to reference during the product design phase.

The following factors will influence the creepage distances:

-

Long-term RMS value of the voltage

-

Pollution degree

-

Material group /CTI

-

Orientation and location of the creepage distance (in order that creepage distances are not adversely affected by the accumulation of pollution for which they were not designed)

-

Shape of insulating surface (effective for pollution degree 3 only, to prevent accumulation of water or pollution)

The following factors will influence the clearance distances:

-

Impulse withstand voltage

-

Temporary overvoltage

-

Steady-state peak voltage or recurring peak voltages

-

Electric field conditions (inhomogeneous/homogeneous)

-

Altitude (a multiplication factor is applied for equipment that operates at altitudes above 2000m)

-

Pollution degree in the micro-environment

For glass, ceramics, or other inorganic insulating materials which do not track, requirements for creepage distances are likely to be the same as the associated clearance distances. Additionally, coating, potting, or molding for protection against pollution also reduces clearance and creepage distances.

Get the enclosure right

The enclosure ensures the user doesn’t have direct contact with any of the product’s dangerous parts, may be used to help contain an internal product fire should it happen, and prevent moisture and dust ingress or accumulation in unwanted areas. The openings may therefore be checked for both accessibility and their ability to contain fire. When reviewing the electrical enclosure for safety requirements, it’s vital to consider that non-metallic enclosure materials have a suitable flammability rating or glow-wire flammability index, if the material is plastic, it is the appropriate thickness for the flammability rating. It is also important that insulating materials, coatings, and PCBs should be resistant to ignition and spread of fire.

Choose pre-approved components

Choosing pre-approved safety-critical components ensures that while the component undergoes testing in the end product, it doesn’t need to be tested separately, which takes additional time and can cause delays. It is worth remembering that custom-made parts may be a solution to a design issue, but they can then later affect compliance: A problem frequently seen at Element is that the product has been modified or is not being used to the correct specification. Element also often sees products that either have the CE Marking but not the necessary accredited test reports or do have the test reports but not to the right or most appropriate Standard. CE Mark Testing Requirements and Certification should be thoroughly checked for the product.

Review technical documentation and instruction manuals

Incorrect or deficient technical documentation is a common cause for a product to fail safety testing.

Required safety-related documentation must include the technical specifications and the name and address of the manufacturer, instructions for use, and a clear explanation of any symbols used on the product.

The instructions not only need to be correct but also easy to understand.

Address the following user issues:

-

How to use the product

-

How not to use the product

-

How to maintain the product

Remember labeling and product markings

Products often fail safety standard requirements due to poor labeling and product markings. Required markings include the manufacturer’s name, trademark and model number and also the appropriate warning markings, and equipment ratings such as supply voltage and frequency.

Think about the product’s environment

Finally, what is the environment that the product is going into, and how is it going to be used? Will it be humid and at risk of moisture exposure, for example? Will the public or only trained individuals be using it? These are all questions that, if the product has undergone pre-qualification testing, will already have been considered but if not, they can cause issues.

It is not unusual for the product’s export markets to still be under review at the testing stage. However, export requirements often result in a product being modified or requiring additional third-party testing, which could have been avoided if pre-compliance procedures had been carried out.

The most cost-effective approach to product development will always be to qualify the prototype design early in the development cycle.

This article was originally published on Element Materials Technology's website and is only reproduced here with their permission. To find out more about Element's work, including their electrical safety testing services visit them here.